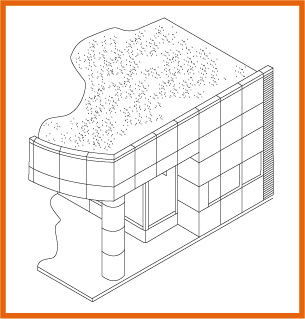

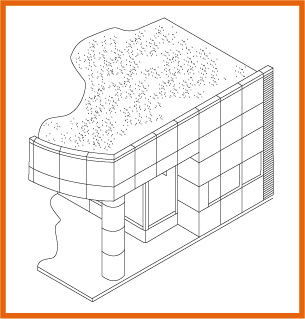

Lu: su composite panels or aluminum-plastic plate, through surface treatment and coating is made of aluminum plate as the surface of the lacquer that bake, PVC plastic board as the core layer, through a series of technological process and processing of composite new material. Aluminum-plastic plate is made by Germany luccin o root (ALUSINGEN), developed and produced by the company, after the Dutch airlines (FORKEN) and rich g Alcoa (an), after the 90 s, the product quality stability, and gradually reached a higher level, because aluminous model board is by nature different kinds of materials (metals and non-metallic), it retains the original composition of material (aluminum metal and nonmetal hexene plastic) the main characteristics and overcome the disadvantages of the original material, and material with many excellent properties. Such as luxury and beauty, gorgeous and colorful decorative; Weather resistance, corrosion resistance, impact resistance, fire prevention, moisture-proof, sound insulation, heat insulation, vibrate resistance; Qualitative light, easy process molding, easy handling installation, can fast the construction features, such as the performance of aluminum-plastic plate opens up broad prospects for the use of.

400-7767-888

400-7767-888